Esimweni esishintsha ngokushesha embonini yezimoto emhlabeni jikelele, umjaho oyaukuhamba kukagesi (i-EV)kanye nokusetshenziswa kahle kukaphethiloli kuye kwashintsha kakhulu ukugxila ekusebenzeni kwenjini kuya kwisayensi yezinto ezibonakalayo. Inhliziyo yalolu shintsho kukhona umqondo wokuthiUkulinganisa Izimoto OkululaNakuba izinsimbi ezisezingeni eliphezulu kanye ne-carbon fiber kuvame ukuba yizindaba ezisematheni,ukuzulazula kwe-fiberglassuvele njengeqhawe elingadunyiswanga, enikeza ikhambi elingabizi kakhulu nelisebenza kahle kakhulu lokukhiqiza izingxenye zezimoto zesizukulwane esilandelayo.

Ushintsho Oluhlelekile: Kungani Kuhambahamba Nge-Fiberglass?

Umkhakha wezimoto okwamanje ubhekene nenselele ekabili: ukunciphisa ukukhishwa kwekhabhoni ezimotweni zenjini yokushisa yangaphakathi (ICE) kanye nokwandisa ububanzi bebhethri lezimoto zikagesi (ama-EV). Ukunciphisa isisindo kuyindlela ephumelela kakhulu yokudonsa kokubili. Imininingwane yemboni iphakamisa ukuthiUkwehla kwesisindo semoto ngo-10%kungaholela ku-Ukuthuthuka okungu-6–8% ekongeni uphethilolinoma ukwanda okukhulu kwebanga le-EV.

Ukuhambahamba nge-fiberglass, ikakhulukaziukuhambahamba ngqofuthiukuzulazula okuhlanganisiwe, inikeza isethi eyingqayizivele yezakhiwo ezenza kube yinto ebalulekile kubahlinzeki be-Tier-1 banamuhla:

Isilinganiso Esingavamile Samandla Nesisindo:Naphezu kokuba lula kakhulu kunensimbi noma i-aluminium, izingxenye eziqiniswe nge-glass fiber roving zingamelana nokucindezeleka okukhulu kwemishini.

Ukumelana Nokugqwala:Ngokungafani nezinsimbi, i-fiberglass ayigqwali, yandisa isikhathi sokuphila kwe-chassis kanye nezingxenye ezingaphansi komzimba.

Ukuvumelana nezimo komklamo:Ukusetshenziswa kokuhambahamba ezinqubweni ezifanai-pultrusionfuthiI-SMC (Inhlanganisela Yokubumba Amashidi)ivumela amajiyometri ayinkimbinkimbi okungenakwenzeka ukuwafeza ngokunyathela insimbi kwendabuko.

Izicelo Eziyinhloko Ezimotweni Zesizukulwane Esilandelayo

Ukuguquguquka kwe-ukuzulazula kwe-fiberglassiboniswa kangcono ngezinhlelo zayo ezahlukahlukene ekwakhiweni kwezimoto zanamuhla.

1. Izivalo zebhethri le-EV

Njengengxenye esindayo kakhulu emotweni kagesi, ibhethri idinga indawo engagcini nje ngokuba lula kodwa futhi evimbela umlilo futhi evikelwe ngogesi.Ukuhambahamba nge-fiberglass, uma ihlanganiswa nama-resin e-thermoset akhethekile, idala indawo ehlanganisiwe evikela amaseli ebhethri ngenkathi ifaka isandla ekuqineni kwesakhiwo semoto.

2. Iziphethu Zamaqabunga kanye Nezinhlelo Zokumiswa

Iziphethu zamaqabunga ensimbi zendabuko zinzima futhi zivame ukukhathala. Ngokusebenzisa i-fiberglass ene-modulus ephezulu ehambahambayo enqubweni yokudonsa amanzi, abakhiqizi bangakhiqiza iziphethu zamaqabunga ezihlanganisiwe ezifinyelela ku-75% elulakunezinsimbi ezihambisana nazo, okunikeza izakhiwo ezingcono zokuthambisa kanye nokuhamba okubushelelezi.

3. Izihlangu Zangaphansi Komuntu kanye Namabhuleki Esakhiwo

Ingxenye engaphansi kwemoto ivezwa emfucumfucwini womgwaqo onzima kanye nomswakama. Ama-thermoplastic aqiniswe nge-fiberglass (CFRTP) asebenzisa i-fibre roving ende anikeza ukumelana okuphezulu komthelela, avikela "izitho ezibalulekile" zemoto ngaphandle kokwengeza isivikelo esikhulu sensimbi esindayo.

Indima Yobuchwepheshe Bokuzulazula Okuthuthukisiwe: I-E-Glass vs. Ingilazi Ene-Modulus Ephakeme

Ukuze kuhlangatshezwane nezidingo eziqinile zemboni yezimoto, akuwona wonke ama-fiberglass roving adalwe ngokulinganayo. Ukukhetha i-fiber kunquma ukusebenza kokuphela kwengxenye.

Ukuhamba Ngengilazi E-E:Izinga lomkhakha, elinikeza ukuvikela ugesi okuhle kakhulu kanye nezakhiwo zemishini ngentengo encintisanayo. Lihlala liyinto ethandwayo kumaphaneli ajwayelekile angaphakathi nangaphandle.

Ukuhamba Okuphezulu Kwe-Modulus (HM):Ngezingxenye zesakhiwo ezidinga ukuqina okukhulu, njengezinsika zophahla noma ozimele beminyango, i-HM roving inikeza i-modulus ehlanganisa igebe phakathi kwefayibha yengilazi yendabuko kanye nefayibha yekhabhoni ebizayo.

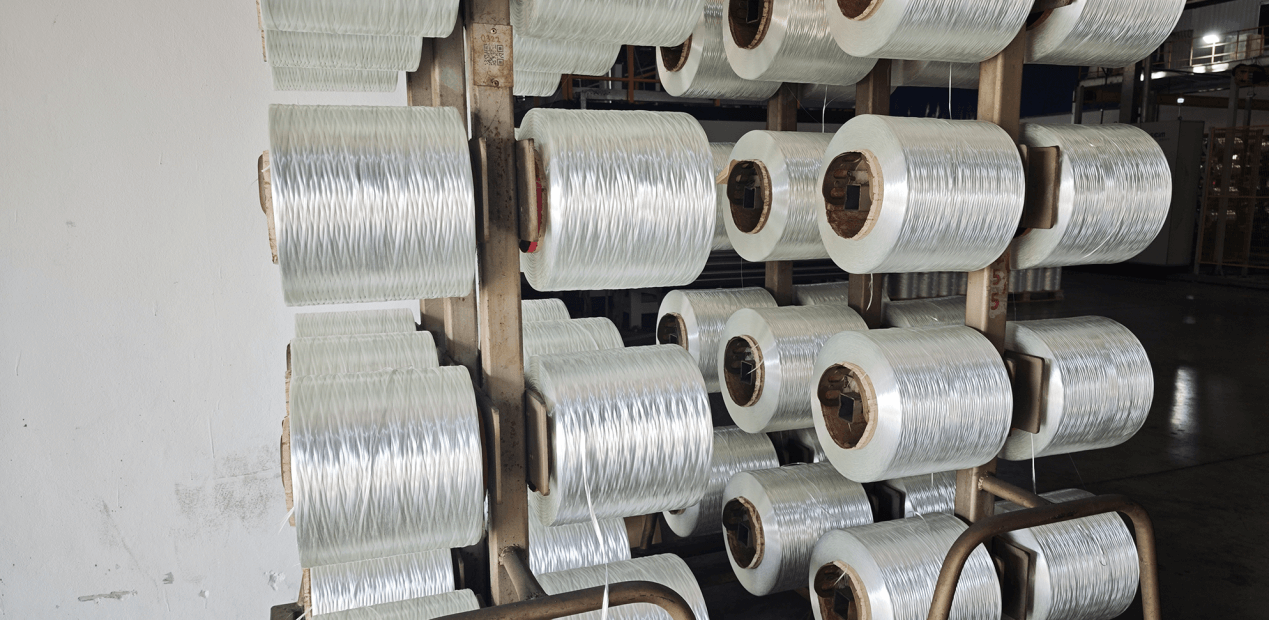

At [I-CQDJ], singochwepheshe ekukhiqizeni i-fiberglass roving nge-advancedizinhlelo zokulinganisa—i-chemical coating esetshenziswa kuma-fiber. Ubukhulu bethu obukhethekile buqinisekisa isibopho esiphelele phakathi kwe-fiber kanye ne-resin matrix (kungakhathaliseki ukuthi yi-Epoxy, i-Polyester, noma i-Polypropylene), okubaluleke kakhulu ekuvimbeleni ukuqhekeka nokuqinisekisa ukuqina kwesikhathi eside ezindaweni zezimoto ezidlidliza kakhulu.

Ukuzinza: Umnotho Ojikelezayo We-Glass Fiber

Umbono ovamile oyiphutha ukuthi izinto ezihlanganisiwe azinabo ubungane nemvelo. Kodwa-ke, ukuqhubekela phambiliukuzulazula kwe-thermoplastic (TP)iyashintsha indaba. Ngokungafani nama-thermosets, ukuzulazula okufakwe ku-thermoplastic kungancibilikiswa futhi kushintshwe, kuvulwe umnyango wokuphinda kusetshenziswe izingxenye zezimoto ekupheleni komjikelezo wokuphila kwemoto. Ngaphezu kwalokho, amandla adingekayo ukukhiqiza ukuzulazula kwe-fiberglass aphansi kakhulu kunalawo e-aluminium noma i-carbon fiber, okunciphisa "i-carbon embedded" yemoto kusukela osukwini lokuqala.

Ukuqonda kwe-SEO Kwabaphathi Bokuthenga

Uma ufuna usizoukuzulazula kwe-fiberglassNgezinhlelo zokusebenza zezimoto, akusanele ukubheka "intengo ngethani." Amaqembu okuthenga manje asegxile kulokhu:

1.Amandla Okudonsa (i-MPa):Ukuqinisekisa ukuthi i-fiber iyakwazi ukusingatha umthwalo.

2.Ukuhambisana:Ingabe ukuzulazula kusebenza nezinhlelo ezithile ze-resin (i-PA6, i-PP, noma i-Epoxy)?

3.Ukungaguquguquki:Ingabe ukuhambahamba kunikeza ukungezwani okufanayo kanye nokungabi namandla okwanele, okuvimbela isikhathi sokungasebenzi emigqeni yokukhiqiza ezenzakalelayo?

Isiphetho

Ikusasa lemboni yezimoto lilula, liqinile, futhi lizinzile. Njengoba singena shí eminyakeni eyishumi, ukuhlanganiswa kweukuzulazula kwe-fiberglassukuba izingxenye zezimoto ezihlelekile nezisebenzayo kuzoshesha kuphela. Ngokushintsha izinsimbi ezisindayo ngezinhlanganisela ezisebenza kahle, abakhiqizi abakhi nje izimoto; baklama ikusasa lokuhamba.

Indlela Esingasiza Ngayo

Njengomkhiqizi ohamba phambili we-fiberglass roving esebenza kahle kakhulu,[I-CQDJ]inikeza izixazululo ezenzelwe wena zochungechunge lokuhlinzekwa kwezimoto. Imikhiqizo yethu yenzelwe ukuthuthukisa izinqubo ze-pultrusion, SMC, kanye ne-LFT (Long Fiber Thermoplastic).

Isikhathi sokuthunyelwe: Disemba-19-2025