Ukukhetha okulungilei-substrate ye-fiberglass, umuntu kumele aqonde izinzuzo zayo, ukungalungi kwayo, kanye nokufaneleka kwayo. Lokhu okulandelayo kuveza izindlela zokukhetha ezijwayelekile. Empeleni, kukhona nenkinga yokumanziswa yi-resin, ngakho-ke indlela engcono kakhulu ukwenza izivivinyo zokumanziswa esikhungweni sokukhiqiza izikebhe ze-fiberglass ukuze kuqinisekiswe.

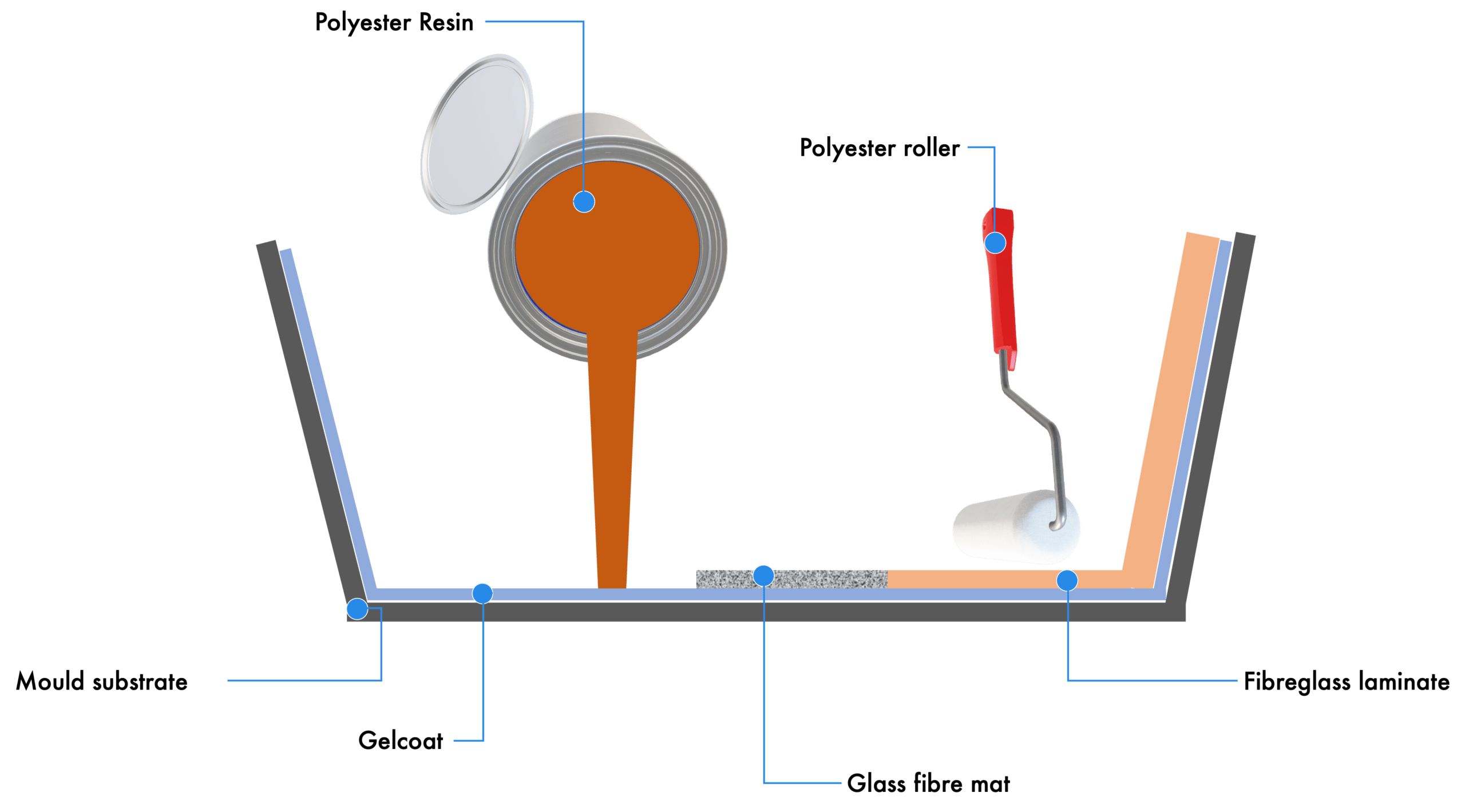

Okwesibili,umbhede we-fiberglassisetshenziswa kakhulu ekubumbeni ngesandla.

Ngokuvamile,umkhiqizo omuhle uhlangabezana nezimo ezilandelayo:

1.Isisindo esifanayo ngeyunithi ngayinye.

Lesi simo sibalulekile njengoba sithinta kokubili ukujiya namandla. Kulula ukukubona ngaphansi kokukhanya, futhi imikhiqizo engalingani kakhulu ingabonakala ngeso lenyama. Ukujiya okufanayo akuqinisekisiwe ngesisindo esifanayo endaweni ngayinye; lokhu kuhlobene ngqo nokuvumelana kwegebe phakathi kwama-roller acindezelayo abandayo. Ukujiya komatilasi okungalingani kuholela kokuqukethwe kwe-resin engalingani emikhiqizweni ye-FRP. Uma umati uthambile, uzomunca i-resin eningi. Ukuhlola ukufana kwesisindo endaweni ngayinye, indlela ejwayelekile ihilela ukusika amasampula omatilasi angu-300mm x 300mm ohlangothini lobubanzi, ukuwabala ngokulandelana, nokuwakala ngokwehlukana ukuze kubalwe ukuphambuka kwesisindo sesampula ngayinye.

2.Ukusatshalaliswa koboya obufanayo ngaphandle kokuqongelela ngokweqile kwendawo.

Ukuhlakazeka kwemicu eqoshiwe kuyinkomba ebalulekile ekukhiqizweni kokuzulazula, okuthinta ukufana kwesisindo somati endaweni ngayinye kanye nesimo sokusatshalaliswa kwemicu kumati. Inqwaba ngayinye yemicu kufanele ihlakazeke ngokuphelele ngemva kokunqunywa kusuka ku-spool (ikhekhe). Uma eminye imicu ingahlakazeki ngokwanele, ingakha izinqwaba ezijiyile, ezinamatheli kumati.

3.Akukho ntambo ewela ebusweni noma ehlukanisayo.

Lokhu kuhlobene namandla okudonsa omshini we-mat. Amandla okudonsa aphansi omshini abonisa ukunamathelana okungekuhle phakathi kwezinqwaba zezintambo.

4.Akukho ukungcola.

Ukuqinisekisa ukuthi umata we-fiberglass oqoshiwe awunawo ukungcola kanye nezinto ezingcolisayo kubalulekile ngezizathu eziningana ezithinta ikhwalithi, ukusebenza, kanye nokuqina komkhiqizo wokugcina ohlanganisiwe.

5.Ukomisa kahle.

Uma umata umanzi, uzowa uma ubekwa bese uthathwa futhi. Umswakama womata kufanele ube ngaphansi kuka-0.2%. Ngezinqubo zokukhiqiza ezijwayelekile, lesi sibonakaliso ngokuvamile siyafaneleka.

6.I-resin emanzi eyanele.

Ukuncibilika kwe-Styrene. Kungcono kakhulu, ukuncibilika kwe-mat ku-resin ye-polyester kufanele kuhlolwe, kodwa lokhu kudla isikhathi futhi kunzima ukukubala. Ukuhlola ukuncibilika kwe-mat ku-styrene esikhundleni se-resin ye-polyester kungabonisa ngokungaqondile ukuncibilika kwe-fiberglass ku-polyester, futhi le ndlela yamukelwa kabanzi futhi ijwayelekile emhlabeni jikelele.

Ngemva kokuba i-resin isifakwe kumathe we-fiberglass, kubalulekile ukuthi imicu ingaphumuli noma inyakaze.

7.Akukho ukukhululeka kwentambo ngemva kokumanziswa yi-resin.

8. Ukunciphisa okulula.

Kwa-CQDJ, singochwepheshe ekukhiqizeni omata be-fiberglass abaqoshiwe bezinga eliphezulu, abaklanyelwe ukuhlangabezana nezidingo ezinzima zezicelo ezahlukahlukene zezimboni. Omata bethu benziwe ngokunemba nangokucophelela, okuqinisekisa ukusebenza okuphezulu, ukuqina, kanye nokuthembeka. Nakhu okwenza omata bethu be-fiberglass abaqoshiwe bahluke:

1.Isisindo Esilinganayo Ngendawo Yeyunithi:

Omata bethuzikhiqizwa ngokucophelela ukuze kugcinwe isisindo esifanayo endaweni ngayinye. Lokhu kuqinisekisa ukujiya namandla ahambisanayo kulo lonke umata, okunikeza ukusebenza okuthembekile kuzo zonke izinhlelo zokusebenza.

2.Ukumanzisa Okuhle Kakhulu kwe-Resin:

Ama-fiberglass mata ethu abonisa ukumanziswa kwe-resin okumangalisayo, okuvumela ukuminyana okuphelele ngama-resin ahlukahlukene. Lokhu kuqinisekisa ukunamathelana okuqinile phakathi kwama-fiber ne-resin, okuholela ezinhlanganisela ezinezakhiwo ezinhle kakhulu zemishini.

3.Ukusatshalaliswa Kwefayibha Okuphakeme:

Siqinisekisa ukuthi imicu eqoshiwe isatshalaliswa ngokulinganayo kulo lonke umata, sivimbele ukuqongelela kwendawo futhi siqinisekise amandla afanayo kanye nokuqina kwesakhiwo.

4.Amandla Aphezulu Okusebenza Kwemishini:

Omata bethu baklanyelwe ukuletha amandla amahle kakhulu okudonseka ngomshini, okuqinisekisa ukuthi imicu ihlala iboshwe kahle futhi izinzile ngesikhathi sokusetshenziswa kwe-resin naphakathi nokuphila komkhiqizo ohlanganisiwe.

5.Ihlanzekile futhi ayinazo izinto ezingcolisayo:

Ukuhlanzeka kuyinto eza kuqala enkambisweni yethu yokukhiqiza. Ama-mat ethu awanazo inhlabathi nezinto ezingcolisayo, okuqinisekisa ukugeleza kwe-resin okuhle kakhulu nokunamathela, kanye nokuphela kobuso obusezingeni eliphezulu komkhiqizo wokugcina ohlanganisiwe.

6.Ukulawula Okuhle Kokomisa Nokuswakama:

Siqinisekisa ukuthi omata bethu bomile kahle, ngokuqukethwe komswakama okungaphansi kuka-0.2%. Lokhu kuvimbela izinkinga ezihlobene nomswakama, njengokuqhekeka komata ngesikhathi sokuphathwa kanye nokumuncwa kwe-resin okungalingani.

7.Ukulula Kokuphatha Nokusebenzisa:

Omata bethu bezintambo eziqoshiwe ze-fiberglass baklanyelwe ukuba kube lula ukubaphatha, ukusika, nokubeka izinto, okwenza kube kuhle kakhulu ekubunjweni ngesandla kanye nezinye izinqubo zokukhiqiza ezihlanganisiwe.

8.Ukuthobela Izindinganiso Zomhlaba Wonke:

Imikhiqizo yethu ihambisana nezindinganiso zomhlaba wonke zezinto ze-fiberglass, okuqinisekisa ukuthi ziyahlangabezana nezidingo zekhwalithi kanye nokusebenza kwamakhasimende emhlabeni jikelele.

Izicelo:

Omata bethu bezintambo eziqoshiwe ze-fiberglass basebenziseka ngezindlela eziningi futhi bangasetshenziswa ezinhlobonhlobo zezicelo, okuhlanganisa:

1.Isolwandle:

Ama-shells esikebhe, amadekhi, nezinye izakhiwo zasolwandle lapho ukuqina nokumelana namanzi nokugqwala kubalulekile khona.

2.Izimoto:

Amaphaneli omzimba, izingxenye zangaphakathi, kanye nezingxenye zesakhiwo ezidinga izinto ezilula kodwa eziqinile.

3.Ukwakhiwa:

Uphahla, amaphaneli odonga, kanye nokuqinisa izakhiwo okuzuza ekuqineni nasekuzinzeni kwezingxenye ze-fiberglass.

4.Izimboni:

Amapayipi, amathangi, nezinye izingxenye zezimboni ezidinga ukumelana nezimo zamakhemikhali ezinzima kanye nokucindezeleka kwemishini.

5.Izimpahla Zabathengi:

Izimpahla zemidlalo, imikhiqizo yokuzijabulisa, nezinye izinto ezidinga izinto ezihlanganisiwe ezisebenza kahle kakhulu.

Umbhede Wethu:

Xhumana nathi:

Inombolo yocingo:+8615823184699

Email: marketing@frp-cqdj.com

Iwebhusayithi: www.frp-cqdj.com

Isikhathi sokuthunyelwe: Meyi-30-2024