Ezweni elikhulu lama-polymer okwenziwa, i-polyester ingomunye wemindeni eguquguqukayo kakhulu futhi esetshenziswa kabanzi. Kodwa-ke, kuvela iphuzu elivamile lokudideka ngamagama athi “i-saturated” kanye ne-“unsaturated” polyester. Nakuba zabelana ngengxenye yegama, izakhiwo zazo zamakhemikhali, izakhiwo, kanye nezicelo zazo zokugcina zihlukile kakhulu.

Ukuqonda lo mehluko akukhona nje okwezemfundo—kubalulekile konjiniyela, abaklami bemikhiqizo, abakhiqizi, kanye nochwepheshe bokuthenga ukuthi bakhethe izinto ezifanele zomsebenzi, baqinisekise ukusebenza kahle, ukuqina, kanye nokusebenza kahle kwezindleko.

Lo mhlahlandlela oqondile uzocacisa lezi zigaba ezimbili ezibalulekile ze-polymer, ukukunikeza ulwazi oludingekayo ukuze wenze isinqumo esinolwazi ngephrojekthi yakho elandelayo.

Umehluko Omkhulu: Konke Kusezibophezelweni Zamakhemikhali

Umehluko oyinhloko usemgogodla wawo wama-molecule, ikakhulukazi ezinhlotsheni zezibopho ze-carbon-carbon ezikhona.

● I-Polyester Engagcwele (I-UPR):Lena “i-polyester” evame kakhulu futhi eqashelwa kabanzi embonini yezinhlanganisela. Uchungechunge lwayo lwama-molecule luqukethe ama-reactive double bonds (C=C). Lawa ma-double bonds angamaphuzu “okungagcwali”, futhi asebenza njengezindawo ezingaba khona zokuxhumanisa.I-UPRAma-s ngokuvamile angama-resin aqinile, afana nesiraphu alula kakhulu ekushiseni kwegumbi.

● I-Polyester Egcwele (SP):Njengoba igama lisho, le polymer inomgogodla oqukethe ngokuphelele izibopho ezi-single (CC). Azikho izibopho ezi-reactive double ezitholakalayo zokuxhumanisa. Ama-polyester agcwele ngokuvamile ayi-thermoplastics eqondile, enesisindo sama-molecule aphezulu futhi eqinile ekushiseni kwegumbi.

Cabanga ngalokhu: I-Unsaturated Polyester iyisethi yezitini ze-Lego ezinezindawo zokuxhuma ezivulekile (izibopho ezimbili), ezilungele ukuvalelwa ndawonye nezinye izitini (i-agent yokuxhumanisa). I-Saturated Polyester iyisethi yezitini esezivele zihlanganiswe ndawonye zibe uchungechunge olude, oluqinile, noluzinzile.

Ukucwila Okujulile: I-Polyester Engagcwele (I-UPR)

Ama-Resin e-Polyester Angagcwalisiwe (Ama-UPR) angama-polymer e-thermosetting. Adinga ukusabela kwamakhemikhali ukuze aphiliswe kusukela kuketshezi abe yinto eqinile engangenwa amanzi.

Inqubo Yekhemistri Nokwelapha:

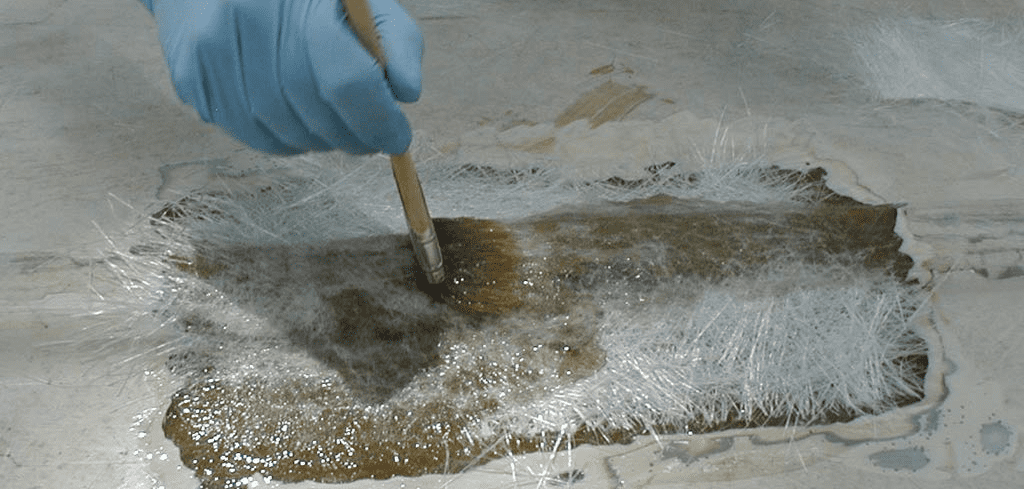

I-UPRama-resinkudalwa ngokuphendula i-diol (isb., i-propylene glycol) ngenhlanganisela ye-dibasic acid egcwalisiwe kanye nengagcwalisiwe (isb., i-Phthalic Anhydride kanye ne-Maleic Anhydride). I-Maleic Anhydride inikeza izibopho ezimbili ezibalulekile.

Umlingo uyenzeka ngesikhathi sokwelapha. II-UPRi-resinixutshwe ne-monomer ephendulayo, ngokuvamile i-Styrene. Uma i-catalyst (i-peroxide ephilayo efanaI-MEKP) uma ingezwa, iqala ukusabela kwe-polymerization yamahhala. Ama-molecule e-styrene axhumanisa izindawo eziseduzeI-UPRamaketanga adlula ezibophweni zawo ezimbili, okudala inethiwekhi eqinile, enezinhlangothi ezintathu. Le nqubo ayinakuguqulwa.

Izakhiwo Eziyinhloko:

Amandla Amangalisayo Okusebenza Ngomshini:Uma sezelaphekile, ziqinile futhi ziqinile.

Ukumelana Okuphezulu Kwamakhemikhali Nokushisa:Imelana kakhulu namanzi, ama-asidi, ama-alkali, kanye nezinyibilikisi.

Ukuqina Okulinganayo:Ukuncishiswa okuphansi ngesikhathi sokuqina, ikakhulukazi uma kuqiniswa.

Ukulula Kokucubungula:Ingasetshenziswa ngezindlela eziningi ezahlukene njengokubeka ngesandla, ukufutha, ukubumba ukudlulisa i-resin (RTM), kanye nokudonsa.

Kuqiza kahle:Ngokuvamile kubiza kancane kunei-epoxyi-resinkanye nezinye izinhlayiya ezisebenza kahle kakhulu.

Izicelo Eziyinhloko:

I-UPRsbangabantu abasebenza kanzimaipulasitiki eqiniswe nge-fiberglass (i-FRP) imboni.

Isolwandle:Ama-shells neziteki zesikebhe.

Ezokuthutha:Amaphaneli omzimba wemoto, ama-fairings amaloli.

Ukwakhiwa:Amaphaneli ezakhiwo, amashidi ophahla, izinto zangasese (amabhavu okugeza, amashawa).

Amapayipi Namathangi:Kwezitshalo zokwelashwa ngamakhemikhali namanzi.

Itshe Lokwenziwa:Izindawo eziqinile zama-countertop.

Ukucwila Okujulile: I-Polyester Egcwele (SP)

Ama-Polyester Agcweleziyimindeni yama-polymer e-thermoplastic. Angancibilikiswa ukushisa, aphinde akhiwe, futhi aqine lapho ephola, inqubo eguquguqukayo.

I-Chemistry kanye nesakhiwo:

Izinhlobo ezivame kakhulu ze-ama-polyester agcweleyi-PET (i-Polyethylene Terephthalate) kanye ne-PBT (i-Polybutylene Terephthalate). Zakhiwa ukusabela kwe-diol ene-diacid egcwele (isb., i-Terephthalic Acid noma i-Dimethyl Terephthalate). Uchungechunge oluvelayo alunazo izindawo zokuxhumanisa, okwenza lube yi-polymer eqondile, eguquguqukayo.

Izakhiwo Eziyinhloko:

Ukuqina Okuphezulu Nokumelana Nomthelela: Ukuqina okuhle kakhulu nokumelana nokuqhekeka.

Ukumelana Okuhle Kwamakhemikhali:Imelana nezinhlobonhlobo zamakhemikhali, yize ingeyona yonke indawo njengeI-UPRs.

Ukuqina kwe-thermoplastic:Kungafakwa umjovo, kukhishwe, futhi kufakwe i-thermoform.

Izakhiwo Ezinhle Kakhulu Zokuvimba:I-PET idume ngezimfanelo zayo zokuvimbela igesi kanye nomswakama.

Ukumelana Nokuguguleka Okuhle Nokuguguleka:Kwenza ifaneleke izingxenye ezihambayo.

Izicelo Eziyinhloko:

Ama-polyester agcwelezitholakala kakhulu kumapulasitiki obunjiniyela kanye nasekupakisheni.

Ukupakisha:I-PET iyinto eyinhloko yokwenza amabhodlela amanzi epulasitiki kanye ne-soda, izitsha zokudla, kanye namaphakethe ama-blister.

Izindwangu:I-PET “i-polyester” edumile esetshenziswa ezingutsheni, emakhaphethini, kanye nasezintanjeni zamathayi.

Ipulasitiki Yobunjiniyela:I-PBT ne-PET zisetshenziselwa izingxenye zezimoto (amagiya, izinzwa, izixhumi), izingxenye zikagesi (izixhumi, amaswishi), kanye nezinto zikagesi zabathengi.

Ithebula Lokuqhathanisa Ikhanda Nekhanda

| Isici | I-Polyester Engagcwele (I-UPR) | I-Polyester Egcwele (SP – isib., i-PET, i-PBT) |

| Isakhiwo Samakhemikhali | Izibopho eziphindwe kabili ezisebenzayo (C=C) emgogodleni | Azikho izibopho eziphindwe kabili; zonke izibopho ezilodwa (CC) |

| Uhlobo lwe-Polymer | I-Thermoset | I-Thermoplastic |

| Ukwelapha/Ukucubungula | Ukwelapha ngamakhemikhali okungenakuguqulwa nge-styrene kanye ne-catalyst | Inqubo yokuncibilika eguqukayo (ukubumba ngomjovo, ukukhipha) |

| Ifomu Elijwayelekile | I-resin yoketshezi | Ama-pellet noma ama-granule aqinile |

| Amandla Ayisihluthulelo | Ukuqina okuphezulu, ukumelana okuhle kwamakhemikhali, izindleko eziphansi | Ukuqina okuphezulu, ukumelana nomthelela, ukuphinde kusetshenziswe |

| Ubuthakathaka Obubalulekile | Ukukhishwa kwe-styrene okubuthakathaka ngesikhathi sokulungiswa, akukwazi ukuphinda kusetshenziswe | Ukumelana nokushisa okuphansi kune-thermosets, kulula kuma-asidi/izisekelo eziqinile |

| Izicelo Eziyinhloko | Izikebhe ze-fiberglass, izingxenye zezimoto, amathangi amakhemikhali | Amabhodlela okuphuza, izindwangu, izingxenye zepulasitiki zobunjiniyela |

Indlela Yokukhetha: Yikuphi Okufanele Iphrojekthi Yakho?

Ukukhetha phakathiI-UPRfuthi i-SP ayivamile ukuba yinkinga uma usuchaze izidingo zakho. Zibuze le mibuzo:

Khetha i-Polyester Engagcwele (I-UPR) uma:

Udinga ingxenye enkulu, eqinile, neqinile ezokhiqizwa ekushiseni kwegumbi (njengesikebhe sesikebhe).

Ukumelana okuphezulu kwamakhemikhali kuyinto eza kuqala (isb., ngamathangi okugcina amakhemikhali).

Usebenzisa amasu okukhiqiza ahlanganisiwe njengokubeka ngesandla noma ukudonsa.

Izindleko ziyisici esibalulekile sokushayela.

Khetha i-Saturated Polyester (SP – PET, PBT) uma:

Udinga ingxenye eqinile, engashayisani (njengegiya noma i-housing yokuvikela).

Usebenzisa ukukhiqiza okuphezulu njengokufaka i-injection molding.

Ukuphinda kusetshenziswe noma ukusetshenziswa kabusha kwezinto kubalulekile kumkhiqizo noma kumkhiqizo wakho.

Udinga izinto ezinhle kakhulu zokubopha ukudla neziphuzo.

Isiphetho: Imindeni Emibili, Igama Elilodwa

Nakuba i-polyester “egcwele” kanye “nengagcwele” izwakala ifana, imelela amagatsha amabili ahlukene omuthi womndeni we-polymer anezindlela ezihlukene.I-Polyester Engagcwele I-ResinIngumpetha wokulungisa ukushisa wezinto ezihlanganisiwe ezinamandla aphezulu, ezingagqwali. I-Saturated Polyester iyihhashi elisebenza nge-thermoplastic ngemuva kwepulasitiki nezindwangu ezivame kakhulu emhlabeni.

Ngokuqonda umehluko wabo oyinhloko wamakhemikhali, ungadlula ukudideka futhi usebenzise izinzuzo ezihlukile zezinto ngazinye. Lolu lwazi lukunika amandla okucacisa i-polymer efanele, okuholela emikhiqizweni engcono, izinqubo ezilungiselelwe, futhi ekugcineni, impumelelo enkulu emakethe.

Isikhathi sokuthunyelwe: Novemba-22-2025