Ezweni lokukhiqiza okuhlanganisiwe, kusetshenziswa izinsiza ezibalulekile ukuthuthukisa i-resin chemistry, ukuthuthukisa isivinini se-pultrusion, kanye nokuhlanza izilinganiso ze-fiber-to-resin. Kodwa-ke, isici esibalulekile sivame ukunganakwa kuze kube yilapho umugqa wokukhiqiza uphela noma iqoqo lezingxenye eziqediwe lihluleka ukuhlolwa kokucindezeleka:indawo yokugcina izintoukuzulazula kwe-fiberglass.

Ukuhambahamba nge-fiberglassakuyona impahla engasebenzi. Kuyinto eyakhiwe kahle kakhulu embozwe “usayizi” wamakhemikhali oyinkimbinkimbi osebenza njengesixhumi phakathi kwengilazi engaphili kanye ne-resin yemvelo. Le khemikhali iyazwela, futhi ukuwohloka kwayo ngesikhathi sokugcina kungaholela ekwehlulekeni okukhulu kokuqina kwesakhiwo.

Kulo mhlahlandlela, sihlola ukuthi izinga lokushisa, umswakama, kanye nemikhuba yokugcina izinto ezisetshenziswayo zilawula kanjani ukusebenza kwezinto zakho zokuqinisa.

Isitha Esingabonakali: Umswakama kanye ne-Hydrolysis

Ingozi ebaluleke kakhulu ekugcinweniukuzulazula kwe-fiberglassiwumswakama. I-fiber yengilazi ithanda amanzi ngokwemvelo (idonsela amanzi). Nakuba imicu yengilazi ngokwayo ihlala isikhathi eside,uhlelo lokulinganisa—ibhuloho lamakhemikhali elivumela i-resin ukuthi “imanzi” futhi inamathele ku-fiber—lisengozini yokutheleleka yi-i-hydrolysis.

Ninii-fiber yengilaziukuhambahambaigcinwa endaweni enomswakama ophezulu:

Ukonakala kosayizi:Umswakama uphula izibopho zamakhemikhali ngaphakathi kosayizi, okwenza kungasebenzi kahle ekukhuthazeni ukunamathela.

Ukumanzi Okubi:Ngesikhathi sokukhiqizwa, i-resin yehluleka ukungena ngokuphelele ku-fiber bundle, okuholela “ezindaweni ezomile” kanye nokungagcwali ku-composite yokugcina.

Isenzo se-Capillary:Uma iziphetho zama-bobbin zivezwa, umswakama ungadonswa ujule ephaketheni ngesenzo se-capillary, okubangela ukusebenza okungahambisani kulo lonke umqulu.

Ukushintshashintsha Kwezinga Lokushisa Nokufuduka Kosayizi

Ngesikhathii-fiber yengilaziinokumelana okuphezulu kokushisa, ubukhulu bezinto eziphilayo abunawo. Uma indawo yokugcina impahla ibhekene nokushisa okukhulu (ngaphezu kuka-35°C/95°F), into eyaziwa ngokuthiukufuduka kosayizikungenzeka. Ukwembozwa kwamakhemikhali kungahamba kancane, kuhlangane phansi kwe-bobbin noma kudale “amabala anamathelayo.”

Ngakolunye uhlangothi, ukugcina uzulazula ezimweni ezibandayo bese ukuthuthela ngokushesha endaweni efudumele yokukhiqiza kuholelaukujiyaLokhu kuqongelela okusheshayo komswakama ebusweni befayibha kuyimbangela ehamba phambili yokwehlukaniswa kwamapayipi anjengesilonda se-filament kanye nemithambo yokucindezela.

Ukuqhathanisa: Izimo Zokugcina Ezifanele Kakhulu Uma Ziqhathaniswa Nezinga Eliphansi

Ukuze usize ithimba lakho lokulawula ikhwalithi ukuthi lihlole izikhungo zakho, bheka ithebula elilandelayo ukuthola izilinganiso ezijwayelekile embonini.

Izindinganiso Zokugcina Izinto Ezihambayo Ze-Fiberglass

| Ipharamitha | Isimo Esifanele (Umkhuba Ongcono Kakhulu) | Isimo Esingaphansi Kwezinga Elijwayelekile (Ingozi Ephakeme) | Umthelela Ekusebenzeni |

| Izinga lokushisa | 5°C kuya ku-35°C (Izinzile) | Ngaphansi kuka-0°C noma ngaphezulu kuka-40°C | Ukulinganisa ukufuduka, imicu ephukile, noma ukujiya. |

| Umswakama Olinganiselwe | 35% kuya ku-65% | Ngaphezulu kuka-75% | Ukushiswa kobukhulu be-hydrolysis, isibopho esibi se-resin-to-fiber. |

| Ukuqondanisa | Amahora angu-24-48 eshabhu ngaphambi kokusebenzisa. | Ukusetshenziswa ngqo kusuka endaweni yokugcina ebanda. | Ukuqhekeka okuncane ku-resin matrix ngenxa yomswakama. |

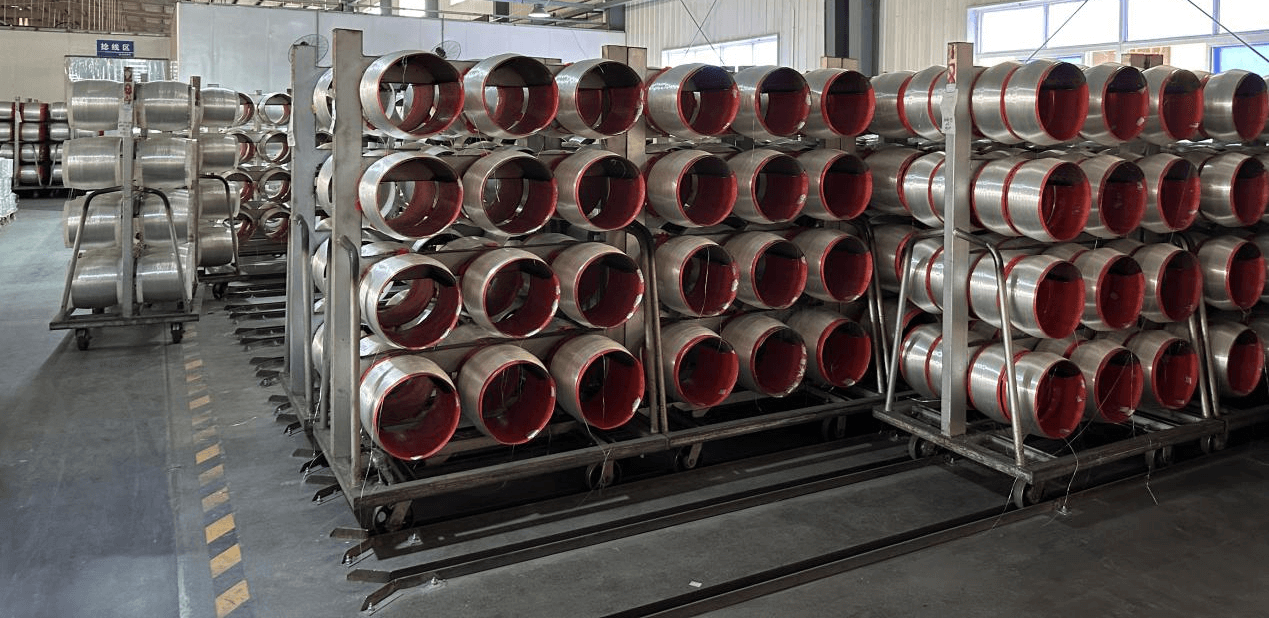

| Ukubeka inqwaba | Ama-pallet okuqala; ukuphakama okuphezulu okungu-2 (uma kuklanywe). | Ama-bobbin akhululekile; ukuphakama okukhulu kokubeka inqwaba. | Ukuguquka komzimba kwama-bobbin; izinkinga zokucindezeleka. |

| Ukuvezwa Kokukhanya | Indawo emnyama noma ephansi ye-UV. | Ukukhanya kwelanga okuqondile (eduze kwamafasitela). | Ukuwohloka kwe-UV kwamakhemikhali okupakisha nokulinganisa. |

Ubuqotho Bomzimba: Izinkinga Zokunqwabelana Nokucindezeleka

Ukuhambahamba nge-fiberglassngokuvamile iboshelwa kuma-bobbin ngokucindezela okuqondile. Uma la ma-bobbin egcinwa ngendlela engafanele—njengokubekwa ngokuvundlile ngaphandle kokusekelwa noma ukuchotshozwa ngaphansi kwesisindo esiningi—i-geometry yangaphakathi yephakheji iyashintsha.

Izinguquko Zokucindezeleka:Ama-bobbin acindezelwe aholela "ekukhokheni" okungalingani ngesikhathi sokuqhuma noma ukugoqwa kwe-filament. Lokhu kuphumela ekutheni eminye imicu ibe lukhuni kuneminye, okudala ukucindezeleka kwangaphakathi engxenyeni eqediwe okungaholela ekugobeni noma ekuhlulekeni kwangaphambi kwesikhathi.

Ukufiphala Nokuphuka:Uma ama-bobbin eshayisana noma edonswa phansi kwendlu yokugcina impahla, izendlalelo zangaphandle zengilazi ziyalimala. Lezi zinhlayiya eziphukile zidala "ukufiphala" emgqeni wokukhiqiza, okungavimba iziqondiso futhi kungcolise ibhavu le-resin.

Indima Yokupakisha: Kungani "Okokuqala" Kungcono Kakhulu

Ukuzulazula kwe-fiberglass esezingeni eliphezuluivame ukulethwa nge-UV-stabilized shrink wrap enamaphakethe e-desiccant. Iphutha elivamile ezindaweni zokukhiqiza ukukhipha lokhu kupakisha ngaphambi kwesikhathi.

I-wrap yokuqala yenza imisebenzi emithathu ebalulekile:

Isithiyo Somswakama:Isebenza njengesivikelo esiyinhloko ekulweni nomswakama ozungezile.

Ukuvimbela Uthuli:Izinto ezincane (uthuli, uthuli lwesarha, noma izingcezu zensimbi) ezivela endaweni yefektri zingaphazamisa isibopho samakhemikhali phakathi kwengilazi ne-resin.

Ukuvimbela:Kuvimbela ukuzulazula “ekugobeni” noma ekuweni kwe-bobbin ngesikhathi sokuphatha.

Izindlela Ezi-5 Ezinhle Zokugcina Ikhwalithi Yokuhamba Ngezimoto

Ukuqinisekisa ukuthi izinto zakho zisebenza njengoba kuchaziwe ngumenzi, sebenzisa lezi zinqubo ezinhlanu zokugcina impahla:

Oqalayo, Oqalayo (FIFO): Ukuhambahamba nge-fiberglassIhlala isikhathi eside, ngokuvamile izinyanga eziyi-6 kuya kweziyi-12. Qinisekisa ukuthi isitokwe esidala sisetshenziswa kuqala ukuvimbela ukuguga kosayizi.

Umthetho Wamahora Angama-24:Njalo letha izinto ezisuka endaweni yokugcina impahla uziyise ehholo lokukhiqiza okungenani amahora angama-24 ngaphambi kokusebenzisa. Lokhu kuvumela ukuthi izinto zifinyelele “ekulinganisweni kokushisa,” kuvimbele ukujiya lapho iphakheji ivulwa.

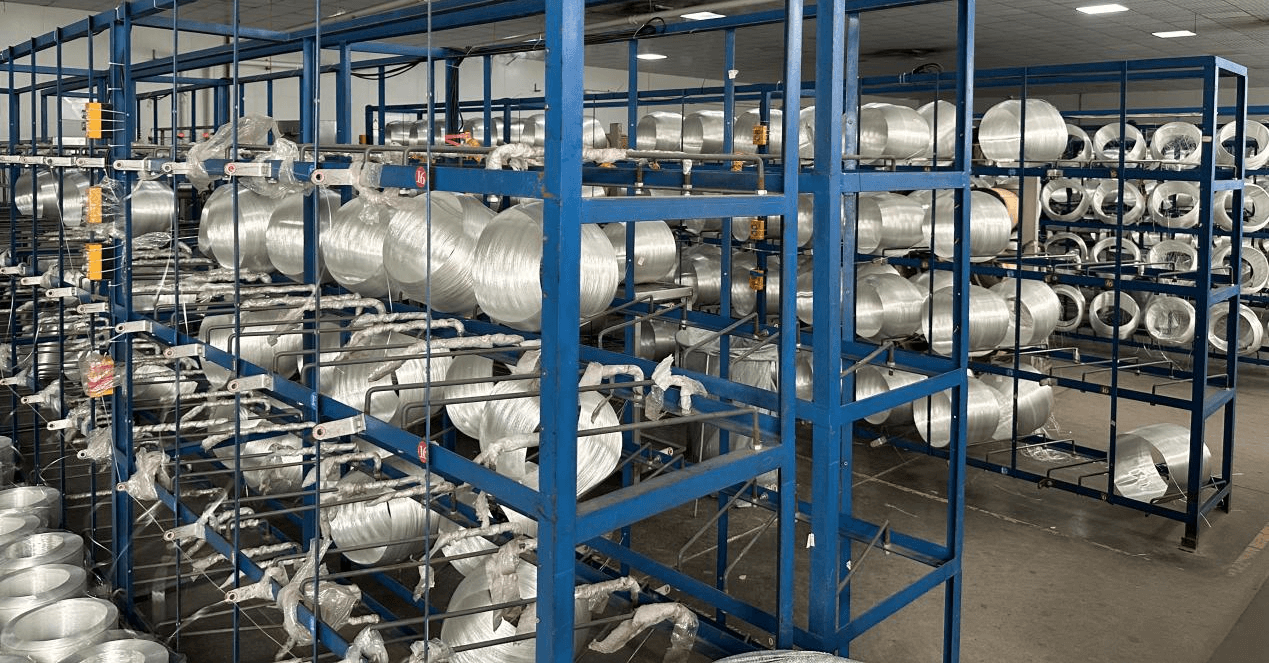

Isitoreji Esiphakanyisiwe:Ungalokothi ugcine ama-pallet azulazulayo ngqo phansi kukhonkolo, okungasusa umswakama. Sebenzisa ama-rack noma ama-pallet okhuni.

Ama-Bobbin Angaphelele Okuvala:Uma i-bobbin ingasetshenziswanga ingxenye kuphela, ungayishiyi ivuliwe emshinini. Yisonge kabusha ngepulasitiki ngaphambi kokuyibuyisela endaweni yokugcina.

I-Monitor ene-Hygrometers:Faka iziqaphi zokushisa nomswakama zedijithali ezindaweni zakho zokugcina. Lolu lwazi lubaluleke kakhulu lapho uxazulula inkinga yokwanda okungazelelwe kwamaphutha okukhiqiza.

Isiphetho: Ukuvikela Ukutshalwa Kwezimali Kwakho

Ukuhambahamba nge-fiberglassiyinto esebenza kahle kakhulu, kodwa ukusebenza kwayo kuyashesha ukubuthaka kuze kube yilapho iphola ngaphakathi kwe-resin matrix. Ngokuphatha izimo zokugcina ngezinga elifanayo lokuhlola njengemingcele yakho yokukhiqiza, unganciphisa kakhulu amazinga okulahlwa, uthuthukise ukuhambisana kwezingxenye, futhi uqinisekise ukuqina kwesikhathi eside kwemikhiqizo yakho ehlanganisiwe.

I-Chongqing Dujiang Composites Co., Ltd.

Xhumana nathi:

Iwebhu: www.frp-cqdj.com/www.cqfiberglass.com/www.cqfrp.ru/www.cqdjfrp.com

I-imeyili:info@cqfiberglass.com/marketing@frp-cqdj.com /marketing01@frp-cqdj.com

I-WhatsApp:+8615823184699

Ucingo:+86-023-67853804

Isikhathi sokuthunyelwe: Jan-09-2026