Ukubeka ngesandla kuyinqubo elula, engabizi futhi ephumelelayo yokubumba i-FRP engadingi imishini eminingi kanye nokutshalwa kwezimali futhi ingaletha imbuyiselo yemali esikhathini esifushane.

1. Ukufutha nokupenda ijazi lejeli

Ukuze kuthuthukiswe futhi kuhlotshiswe isimo sobuso bemikhiqizo ye-FRP, kwandiswe inani lomkhiqizo, futhi kuqinisekiswe ukuthi ungqimba lwangaphakathi lwe-FRP aluguguleki futhi kwandiswe impilo yesevisi yomkhiqizo, ubuso bokusebenza bomkhiqizo ngokuvamile benziwa ungqimba olune-pigment paste (color paste), okuqukethwe okuphezulu kwe-resin kwengqimba yokunamathela, kungaba yi-resin emsulwa, kodwa futhi kuthuthukiswe nge-surface felt. Lolu ngqimba lubizwa ngokuthi ungqimba lwe-gel coat (olubizwa nangokuthi ungqimba lwe-surface noma ungqimba lokuhlobisa). Ikhwalithi yongqimba lwe-gel coat ithinta ngqo ikhwalithi yangaphandle yomkhiqizo kanye nokumelana nesimo sezulu, ukumelana namanzi kanye nokumelana nokuguguleka kwe-chemical media, njll. Ngakho-ke, amaphuzu alandelayo kufanele aqashelwe lapho kufafazwa noma kupendwa ungqimba lwe-gel coat.

2. Ukunqunywa kwendlela yenqubo

Indlela yenqubo ihlobene nezici ezahlukahlukene njengekhwalithi yomkhiqizo, izindleko zomkhiqizo kanye nomjikelezo wokukhiqiza (ukusebenza kahle kokukhiqiza). Ngakho-ke, ngaphambi kokuhlela ukukhiqiza, kubalulekile ukuqonda okuphelele izimo zobuchwepheshe (indawo, izinga lokushisa, okuphakathi, umthwalo ……, njll.), isakhiwo somkhiqizo, inani lokukhiqiza kanye nezimo zokwakha lapho umkhiqizo usetshenziswa, futhi ngemva kokuhlaziya nokucwaninga, ukuze kutholakale uhlelo lwenqubo yokubumba, ngokuvamile, izici ezilandelayo kufanele zicatshangelwe.

3. Okuqukethwe okuyinhloko komklamo wenqubo

(1) Ngokuya ngezidingo zobuchwepheshe zomkhiqizo ukukhetha izinto ezifanele (izinto zokuqinisa, izinto zokwakha nezinye izinto ezisizayo, njll.). Ekukhetheni izinto zokusetshenziswa, izici ezilandelayo zicatshangelwa kakhulu.

①Kungakhathaliseki ukuthi umkhiqizo uthintana ne-acid ne-alkaline media, uhlobo lwe-media, ukuhlushwa, izinga lokushisa lokusetshenziswa, isikhathi sokuxhumana, njll.

②Kungakhathaliseki ukuthi kunezidingo zokusebenza ezifana nokudlulisa ukukhanya, into evimbela ilangabi, njll.

③Ngokuphathelene nezakhiwo zemishini, kungaba umthwalo oguquguqukayo noma ongaguquki.

④Kukhona noma kungekho ukuvimbela ukuvuza kanye nezinye izidingo ezikhethekile.

(2) Nquma isakhiwo sesikhunta kanye nezinto ezisetshenziswayo.

(3) Ukukhetha i-ejenti yokukhulula.

(4) Nquma ukuthi isistimu yokulungisa i-resin ilingana kanjani futhi iqine kangakanani.

(5) Ngokuya ngokujiya komkhiqizo kanye nezidingo zamandla, nquma izinhlobo zezinto zokuqinisa, imininingwane, inani lezendlalelo kanye nendlela yokubeka izendlalelo.

(6) Ukulungiswa kwezinqubo zenqubo yokubumba.

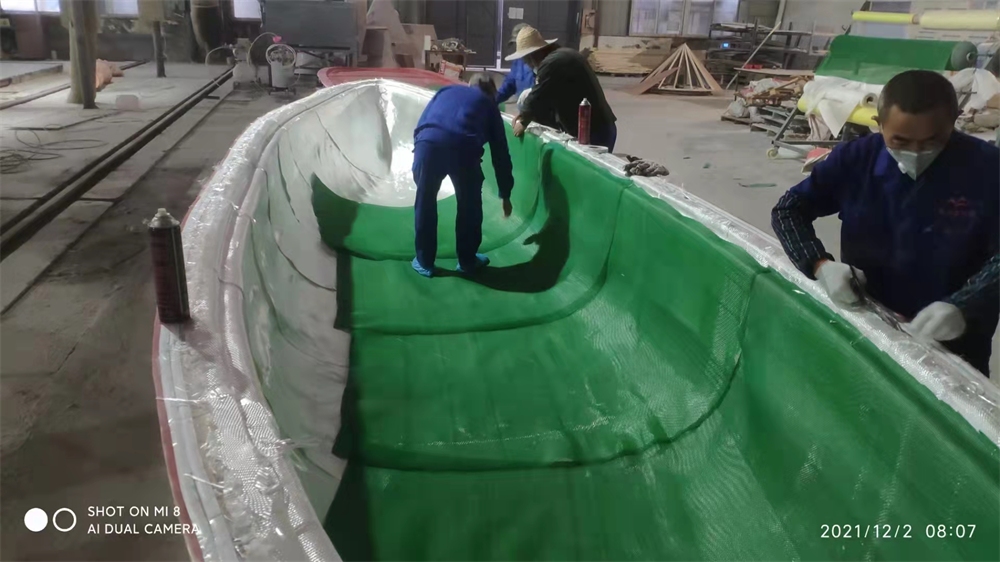

4. Uhlelo lokunamathisela ungqimba lwepulasitiki oluqiniswe ngefayibha yengilazi

Ukubeka ngesandla kuyinqubo ebalulekile yenqubo yokubumba ngesandla, kumele kube nokusebenza kahle ukuze kufezwe okuqukethwe kwe-resin okusheshayo, okunembile, okufanayo, kungabikho amabhamuza asobala, kungabikho ukuminyana okubi, kungabikho umonakalo ku-fiber kanye nobuso bomkhiqizo obuyisicaba, ukuqinisekisa ikhwalithi yemikhiqizo. Ngakho-ke, nakuba umsebenzi wokunamathisela ulula, akulula kakhulu ukwenza imikhiqizo ibe kahle, futhi kufanele ithathwe ngokungathi sína.

(1) Ukulawula ukujiya

I-fiber yengilaziUkulawulwa kobukhulu bemikhiqizo yepulasitiki eqinisiwe, inqubo yokuklanywa kwenqubo yokunamathisela ngesandla kanye nenqubo yokukhiqiza izobhekana nezinkinga zobuchwepheshe, uma sazi ubukhulu obudingekayo bomkhiqizo, kuyadingeka ukubala ukuze kunqunywe i-resin, okuqukethwe kokugcwalisa kanye nezinto zokuqinisa ezisetshenziswa ezinhlotsheni, inani lezingqimba. Bese ubala ubukhulu bayo obulinganiselwe ngokwefomula elandelayo.

(2) Ukubalwa komthamo we-resin

Umthamo we-resin we-FRP uyipharamitha ebalulekile yenqubo, engabalwa ngezindlela ezimbili ezilandelayo.

Ifomula yokubala inani le-resin ibalwa ngokwesimiso sokugcwalisa igebe, yazi kuphela ubunzima bendawo yendwangu yengilazi kanye nobukhulu obufanayo (ungqimba lwe-ingilaziifayibhaindwangu okulingana nobukhulu bomkhiqizo), ungabala inani le-resin eliqukethwe ku-FRP

I-B ibalwa ngokubala kuqala isisindo somkhiqizo bese kunqunywa okuqukethwe kwephesenti lesisindo sefayibha yengilazi.

(3)Ingilaziifayibhauhlelo lokunamathisela indwangu

Imikhiqizo enesendlalelo se-gelcoat, i-gelcoat ayikwazi ukuhlanganiswa nokungcola, inamathiselwe ngaphambi kohlelo kufanele ivimbele ukungcola phakathi kwesendlalelo se-gelcoat kanye nesendlalelo esingemuva, ukuze kungabangela ukubopha okubi phakathi kwezingqimba, futhi kuthinte ikhwalithi yemikhiqizo. Isendlalelo se-gelcoat singathuthukiswa ngeubusoumataUhlelo lokunamathisela kufanele luqaphele ukufakwa kwe-resin kwemicu yengilazi, kuqala lwenze ukungena kwe-resin kuyo yonke indawo ye-fiber bundle, bese lwenza umoya ongaphakathi kwe-fiber bundle uthathelwe indawo yi-resin ngokuphelele. Kubaluleke kakhulu ukuqinisekisa ukuthi ungqimba lokuqala lwezinto zokuqinisa lufakwe ngokuphelele yi-resin futhi lufakwe eduze, ikakhulukazi kweminye imikhiqizo ezosetshenziswa ezimweni zokushisa eziphakeme. Ukufakwa okubi kanye ne-lamination embi kungashiya umoya uzungeze ungqimba lwe-gelcoat, futhi lo moya oshiywe ngemuva ungabangela amabhamuza omoya ngesikhathi senqubo yokwelapha kanye nokusetshenziswa komkhiqizo ngenxa yokwanda kokushisa.

Uhlelo lokubeka ngesandla, kuqala engqimbeni yejazi lejeli noma ebusweni bokwakha isikhunta ngebhulashi, i-scraper noma i-impregnation roller kanye nenye ithuluzi lokunamathisela ngesandla elihlanganiswe ngokulinganayo ngengqimba ye-resin elungisiwe, bese ubeka ungqimba lwezinto zokuqinisa ezisikiwe (njengemichilo evundlile, indwangu encane noma i-surface felt, njll.), kulandele amathuluzi okwakha azobhulashwa abe yi-flat, acindezelwe, ukuze alingane kahle, futhi anake ukukhishwa kwama-bubble omoya, ukuze indwangu yengilazi igcwale ngokuphelele, hhayi izendlalelo ezimbili noma ngaphezulu zezinto zokuqinisa ngesikhathi esisodwa. Phinda umsebenzi ongenhla, kuze kube yilapho ubukhulu obudingekayo ngumklamo.

Uma i-geometry yomkhiqizo iyinkimbinkimbi kakhulu, kwezinye izindawo lapho izinto zokuqinisa zingabekwanga phansi, amabhamuza akulula ukuwakhipha, izikele zingasetshenziswa ukusika indawo futhi ziyenze ibe yithafa, kufanele kuqashelwe ukuthi ungqimba ngalunye kufanele lube izingxenye ezihlanganisiwe zokusikwa, ukuze kungabangela ukulahlekelwa amandla.

Ezingxenyeni ezine-engeli ethile, zingagcwaliswa ngei-fiber yengilazi kanye ne-resin. Uma ezinye izingxenye zomkhiqizo zinkulu kakhulu, zingaqiniswa noma ziqiniswe ngendlela efanele endaweni ukuze kuhlangatshezwane nezidingo zokusetshenziswa.

Njengoba isiqondiso sefayibha yendwangu sihlukile, amandla ayo nawo ahlukile. Isiqondiso sokubekwa kwefayibha yendwanguindwangu yefayibha yengilaziisetshenziswa futhi indlela yokubeka kufanele yenziwe ngokwezidingo zenqubo.

(4) ukucutshungulwa komthungo wethanga

Uma ungqimba olufanayo lwemicu luqhubeka ngangokunokwenzeka, gwema ukusikwa noma ukuxhunywa ngokungahleliwe, kodwa ngenxa yobukhulu bomkhiqizo, ubunzima kanye nezinye izizathu zemikhawulo okufanele ifinyelelwe, uhlelo lokunamathisela lungathathwa lapho kubekwa isinqe, umthungo we-lap kufanele uhambisane kuze kube yilapho i-paste ifinyelela ubukhulu obudingekayo ngumkhiqizo. Uma unamathisela, i-resin ifakwa amathuluzi anjengemabhulashi, ama-roller nama-bubble roller bese ama-bubble omoya akhishwa.

Uma isidingo samandla siphezulu, ukuze kuqinisekiswe amandla omkhiqizo, i-lap joint kufanele isetshenziswe phakathi kwezingcezu ezimbili zendwangu, ububanzi be-lap joint bungaba ngu-50 mm. Ngesikhathi esifanayo, i-lap joint yesendlalelo ngasinye kufanele ilinganiswe ngangokunokwenzeka.

(3)Ukubeka izandla phezulukweumucu oqoshiwe umatas

Uma usebenzisa i-felt emfushane njengento yokuqinisa, kungcono ukusebenzisa osayizi abahlukene bama-roller okufaka i-impregnation ukuze usebenze, ngoba ama-roller okufaka i-impregnation asebenza kahle kakhulu ekukhipheni amabhamuza ku-resin. Uma kungekho thuluzi elinjalo futhi ukufakwa kwe-impregnation kudinga ukwenziwa ngebhulashi, i-resin kufanele isetshenziswe ngendlela yebhulashi elikhomba, ngaphandle kwalokho imicu izophanjaniswa futhi ihlukaniswe ukuze ukusatshalaliswa kungabi okufanayo futhi ubukhulu bungafani. Izinto zokuqinisa ezibekwe ekhoneni elijulile langaphakathi, uma ibhulashi noma i-impregnation roller kunzima ukuyenza ilingane kahle, ingalungiswa futhi icindezelwe ngesandla.

Uma unikeza ukubekwa, sebenzisa i-roller yeglue ukufaka iglue ebusweni besikhunta, bese ubeka uhlaka olusikiwe ngesandla faka i-mold bese uyilungisa, bese usebenzisa i-glue roller eglue, uyigoqe ngokuphindaphindiwe, ukuze i-resin glue icwiliswe ku-mat, bese usebenzisa i-glue bubble roller ukuze ucindezele i-glue ngaphakathi ku-mat ebusweni bese ukhipha ama-bubble emoyeni, bese unamathisela ungqimba lwesibili. Uma uhlangana nekhona, ungadabula i-mat ngesandla ukuze kube lula ukugoqa, futhi i-lap phakathi kwezingcezu ezimbili ze-mat ingaba ngu-50mm.

Imikhiqizo eminingi ingasebenzisa futhiomata abaqoshiwekanye nendwangu yengilazi yefayibha ehlukile, njengezinkampani zaseJapan zokunamathisela isikebhe sokudoba ukusetshenziswa kwendlela yokunamathisela ehlukile, kubikwa ukuthi indlela yokukhiqiza imikhiqizo ye-FRP isebenza kahle.

(6) Uhlelo lokunamathisela lwemikhiqizo enodonga olujiyile

Imikhiqizo enobukhulu obungaphansi kuka-8 mm ingakhiwa kanye, futhi uma ubukhulu bomkhiqizo bungaphezu kuka-8 mm, kufanele ihlukaniswe ibe ukubumba okuningi, ngaphandle kwalokho umkhiqizo uzophulukiswa ngenxa yokushabalalisa ukushisa okubi okuholela ekushiseni, ekushintsheni kombala, okuthinta ukusebenza komkhiqizo. Emikhiqizweni enokubunjwa okuningi, ama-burrs nama-bubbles akhiwe ngemuva kokugcoba kokuqala kufanele asuswe ngefosholo ngaphambi kokuqhubeka nokunamathisela umgwaqo olandelayo. Ngokuvamile, kunconywa ukuthi ubukhulu bokubumba okukodwa akufanele budlule u-5 mm, kodwa kukhona nokukhishwa kokushisa okuphansi kanye nama-resin anciphayo aphansi aklanyelwe ukubumba imikhiqizo emikhulu, futhi ubukhulu balo resin bukhulu kakhulu kokubumba okukodwa.

I-Chongqing Dujiang Composites Co., Ltd.

Xhumana nathi:

Email:marketing@frp-cqdj.com

I-WhatsApp:+8615823184699

Ucingo: +86 023-67853804

Iwebhu:www.frp-cqdj.com

Isikhathi sokuthunyelwe: Okthoba-09-2022